|

If this message is not displayed correctly, please click here.

|

August 2025 | Trade Fair News

|

|

|

Taipei International Industrial Automation Exhibition

|

|

Dear Visitor,

We cordially invite you to join us at the German Pavilion at this year’s Taipei International Industrial Automation exhibition. We, DEinternational Taiwan Ltd., the service unit of the German Trade Office Taipei (AHK Taiwan), have years of experience in organizing German Pavilions at Taiwan’s trade exhibitions. Our exhibitors benefit from our networking expertise and enjoy an extensive service package. Together we strengthen the brand ‘Made in Germany’.

Automation Taipei has been successfully held since 1987. This exhibition combines different resources from the industries, providing a professional interaction platform which enables the exhibitors to present their products in a more efficient, cost/labor- and energy saving way. Moreover, we hope the exhibition will allow domestic and overseas buyers to visit various newest automation equipment and technology under one roof at the same time. The Taipei International Industrial Automation exhibition will take place from August 20th until the 23rd at the TaiNEX hall 1 & 2. Last year, the 2024 show attracted a total of 314,756 visitors. Taipei’s Automation is the ideal platform to learn about innovations as well as trends in Industry 4.0 and Smart Manufacturing and to acquire new business partners.

Germany and Taiwan share similar economies. Both are highly innovative and export-driven with a large share of “hidden champions” deeply embedded in the supply chains. The automation industry is a key sector in German-Taiwanese cooperation. In this special edition newsletter, you will find our featured editorials about all exhibitors in our German Pavilion, their profiles, and an overview of their products and services. Also please feel free to contact our Senior Project Manager Trade Fair Services Mr. Pinchao Huang (huang.pinchao@taiwan.ahk.de) in case you have any inquiry that we may assist you with.

Enjoy this special edition, we are looking forward to your visit at our German Pavilion!

Best regards,

Trade Fair Team

DEinternational Taiwan Ltd.

Service Unit of the German Trade Office Taipei |

German Pavilion Venue

- Nangang Exhibition Center, Hall 1, 1F (Entrance of Zone J-K )

|

|

Key Figures from Automation 2024

- Total Visitors: 314,756

- Exhibitors: 842

- Booths: 3,435

|

|

Product Group

- Industrial Automation

- Robort Technology

- Industrial Automation ICT and Software

- Handware and Factory Equipment

- Machine Tool & Machinery

|

|

|

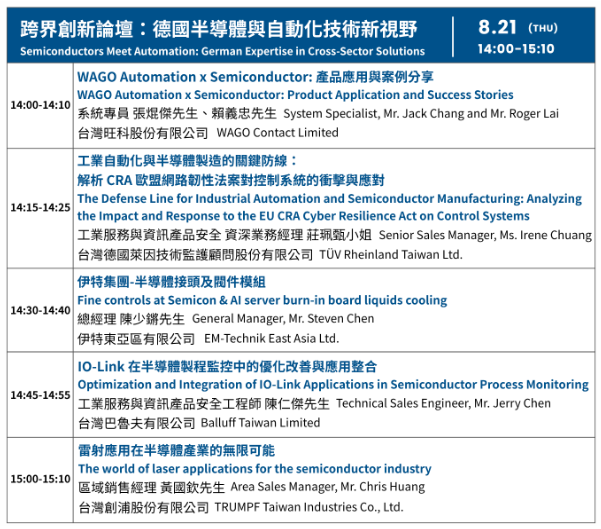

German Pavilion Event

German Pavilion will host “Industry Solutions Session” at the 2025 Taipei Automation, inviting several German experts to share their insights on the future prospects and practical experiences of the automation industry. Following the session, there will also be a German Pavilion Happy Hour, where attendees can network and exchange ideas with industry professionals in a relaxed atmosphere accompanied by German beer, fostering new collaborations and connections.

- Event Venue: Nangang Exhibition Center Hall 1, 1F, German Pavilion (J331)

Registered online to receive a special gift!

The event agenda and registration link are as follows:

|

|

German Pavilion Exhibitors (in Alphabetical Order)

|

|

|

Please click the company name to get the information

|

|

Balluff Taiwan Ltd. (K304)

|

|

|

Balluff is a medium-sized company that has been family-run for four generations, was founded in Neuhausen auf den Fildern near Stuttgart and now has grown into a cosmopolitan, leading global player. We are a sensor and automation specialist with tradition and long-standing customer relationships, which at the same time is an important innovation partner for its customers.

Our company opened up to the international market at a very early stage. In the early 80s, Balluff began to continuously expand its production and sales network. Today, Balluff is no longer just at home in Neuhausen, but in Europe, Asia, North and South America and all other important markets - in 68 countries worldwide. This allows us to better understand and serve our customers and give them exactly what they need: high-quality sensor, identification and image processing solutions, including network technology and software for all their automation requirements. As a future-oriented company, we not only focus on the classic automation areas, but also respond to the continuously changing market needs of customers and a digital, networked world: As an empowerer, we enable our customers to achieve sustainable success in their digital transformation with IIoT-capable hardware, middleware and systems.

|

|

|

Products / Service Introduction

|

|

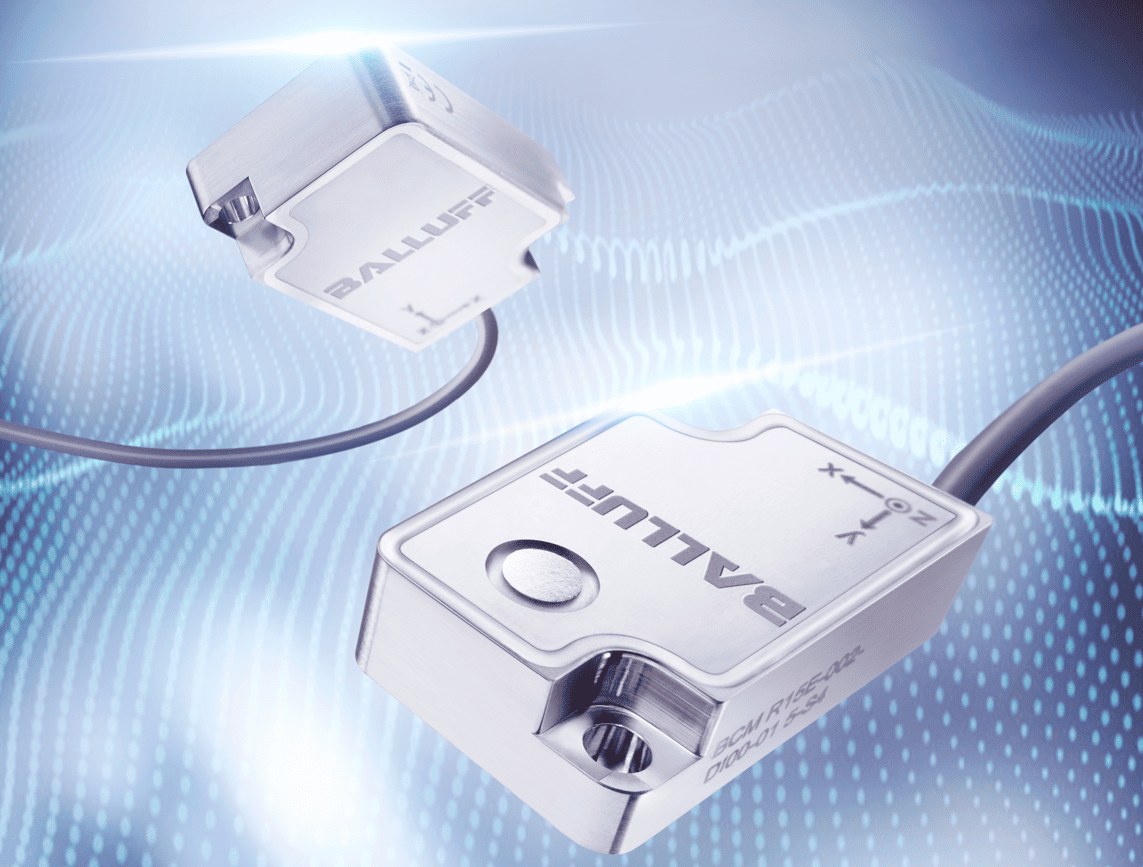

IO-Link Condition Monitoring

|

|

|

Condition monitoring systems and their components contribute to the efficient and trouble-free operation of machines and plants in industry. Disruptions in the production process due to unplanned downtimes can be prevented by using sensors. Monitoring devices such as vibration, temperature, pressure and level sensors, provide data on the condition of a plant. When processed, this data provides information for the upkeep of machines and thus enables preventative and predictive maintenance. These condition monitoring systems allow changes, such as wear on individual components, to be detected more quickly and machine maintenance to be better coordinated.

|

|

|

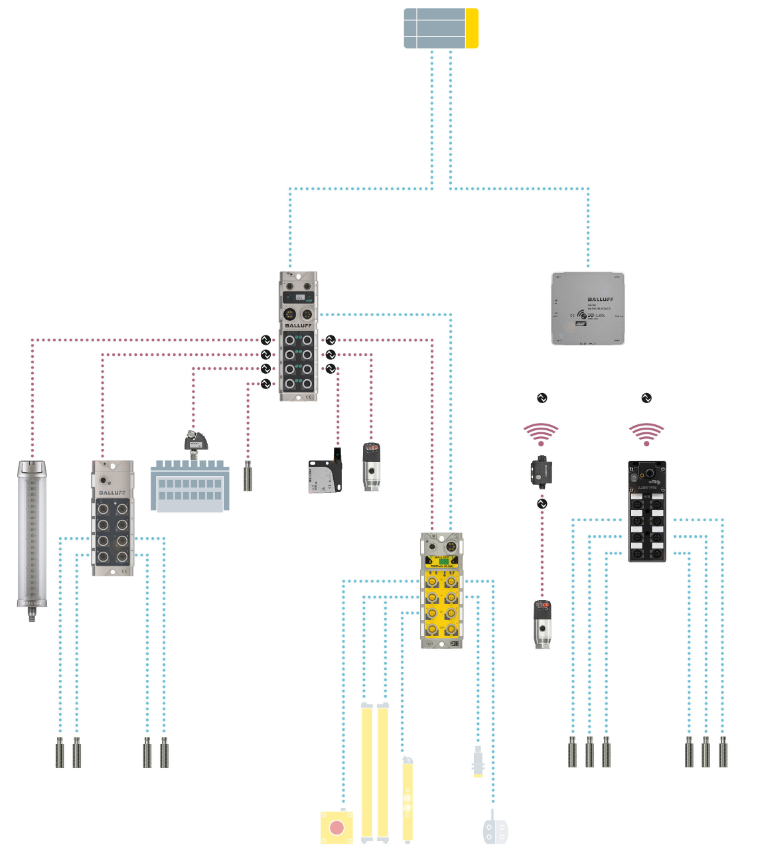

To reliably control and monitor your machines and systems, you need professional industrial communication and network technology. The requirements for industrial networks are extensive and diverse. The ever-increasing volume of data and complex communication require powerful and reliable components that are capable of transporting information across all levels.

This is especially true when high protection classes, robustness, use at high temperatures or special interfaces and connections for the greatest possible safety are required.

The intelligent combination of powerful industrial networks with the IO-Link communication standard enables the reliable and flexible exchange of information in a wide range of applications.

Balluff thus enables you to optimally network your network components and provides an important building block for the industrial automation of your company.

|

|

|

|

All our capacitive level sensors, whether designed for contact or non-contact applications, are equipped with our patented Smart Level technology. This advanced feature allows the sensors to compensate for moisture, foam, and adhesion of any kind, ensuring their effectiveness even through glass and plastic barriers up to 10mm thick. This makes the sensors ideal as fill level sensors for conductive media.

Special features of our capacitive level sensors

- Capacitive level measurement of plastic granulates, grain, feed and wood pellets, oils, aqueous liquids, acids, alkalis, conductive powder, bulk solids, etc.

- Large selection of configurations and housing materials as well as cost-effective versions

- Easy adjustment and setup, also via IO-Link

- Patented Smart Level technology compensates for adhesion, moisture, and foam

|

|

|

|

camLine has been recognized as a valued IT solution partner for high-tech manufacturing over the past 35 years. Industry automation systems are based on MES/MOM modules. Numerous implementations can be found in semiconductors, electronics, automotives, solar, batteries, medical devices, and renewable energies across Europe, North America, and APAC. In addition to service domains on quality assurance, process integrity, production logistics, OEE, monitoring and reporting, camLine’s solutions feature the orchestration of shop floor activities among different communication layers. As part of Elisa IndustrIQ, AI and machine learning (AI/ML) techniques are integrated in statistical methods to foster optimal engineering analysis and defect control.

|

|

|

Products / Service Introduction

|

|

|

LineWorks SQM

- Incoming material quality control

Automates supplier quality and incoming material management.

- LineWorks SPACE

- Advanced statistical process control

Enables real-time process monitoring and statistical process control (SPC).

- LineWorks CQM

- Outgoing material quality control

Enhance quality assurance by automating customizable electronic Certificate of Analysis (eCOA) creation.

- LineWorks RM

- Recipe management system

Centralizes recipe and parameter management for manufacturing.

- LineWorks MMS

- Track and monitor equipment

Provides real-time equipment monitoring and maintenance management

- LineWorks Maima

- Maintenance management

Maintenance software for planning and executing preventive and corrective tasks

|

|

|

|

RACE™ Suite is specifically designed to optimize and streamline automated material handling systems for high-volume manufacturing. With over 20 years of successful implementations worldwide, RACE™ offers the robust stability required by 24/7 factory automation systems.

RACE MCS™ is the world’s only third generation material control system in the semiconductor industry. Equipped with integrated fleet management capabilities, RACE MCS™ delivers precision and accuracy in material control, benefiting any industry seeking to upgrade its operations through automation.

RES-Q™ acts as separate Digital Twins with approximately 97% accuracy for all storage and material transport systems as well as the operational environment.

|

|

|

|

The Comprehensive and Scalable MES Solution for Discrete Manufacturing

Discrete manufacturers must accelerate production ramp-up, maintain high quality and yield, and optimize operational costs to stay competitive. InFrame Synapse provides a comprehensive solution that fundamentally covers all essential core functions of a Manufacturing Execution System (MES). As a powerful and scalable product family, it includes InFrame Synapse MES for efficient production execution and InFrame Synapse EQC for seamless equipment integration. Its open architecture not only ensures a fully connected digital infrastructure but also allows effortless expansion with specialized modules from the LineWorks Suite.

|

|

|

Canaan Electric Corp. (J429)

|

|

|

Canaan specializes in industrial and building automation, offering both in-house developed CEC timers, counters, and position controllers, as well as distributing a diverse range of high-quality solutions from leading European and Japanese brands. Our product portfolio includes various sensors, controllers, and transmission connectors, catering to industries such as electronics and semiconductors, metal processing, plastic and rubber molding, food and beverage packaging, logistics and warehousing, refrigeration, and HVAC systems. We are committed to delivering high-stability and high-performance control components for a wide array of applications.

Furthermore, we actively integrate RFID industrial identification systems and remote monitoring solutions, embracing Industrial IoT (IIoT) technologies to develop smarter and more responsive automation solutions for our customers. With years of expertise in the automation industry, we uphold our corporate vision of “Co-creating an Intelligent Automated Future”, striving to provide the most professional services and the most comprehensive product selection, empowering our clients to enhance productivity and competitiveness.

|

|

|

Products / Service Introduction

|

|

Photoelectric sensors(general/slim/MiniSlot/Fiber optic)

|

|

|

Photoelectric sensors check presence, shape, colour, distance, and thickness - optimised for robotics, automation, assembly, and handling.

We offer every light type, whether red light, infrared, blue light or laser technology, in different ranges. With and without background suppression. Various designs – also in mini slim version minislot version. General and fiber Optic) – ensure a wide variety of possible applications.

|

|

|

Full-process monitoring~Fexibility to use

- Compatible with PLC programs to save development time

- Easy to adjusting and positioning, and replaceing proximity switches.

- Meet the needs of multi-point positioning and monitor for the whole process

- Reduce costs by replacing analog cards

- Using mm as distance unit, easy to use and identify

- With external Tech-in setting function

- Support PNP, NPN setting

|

|

|

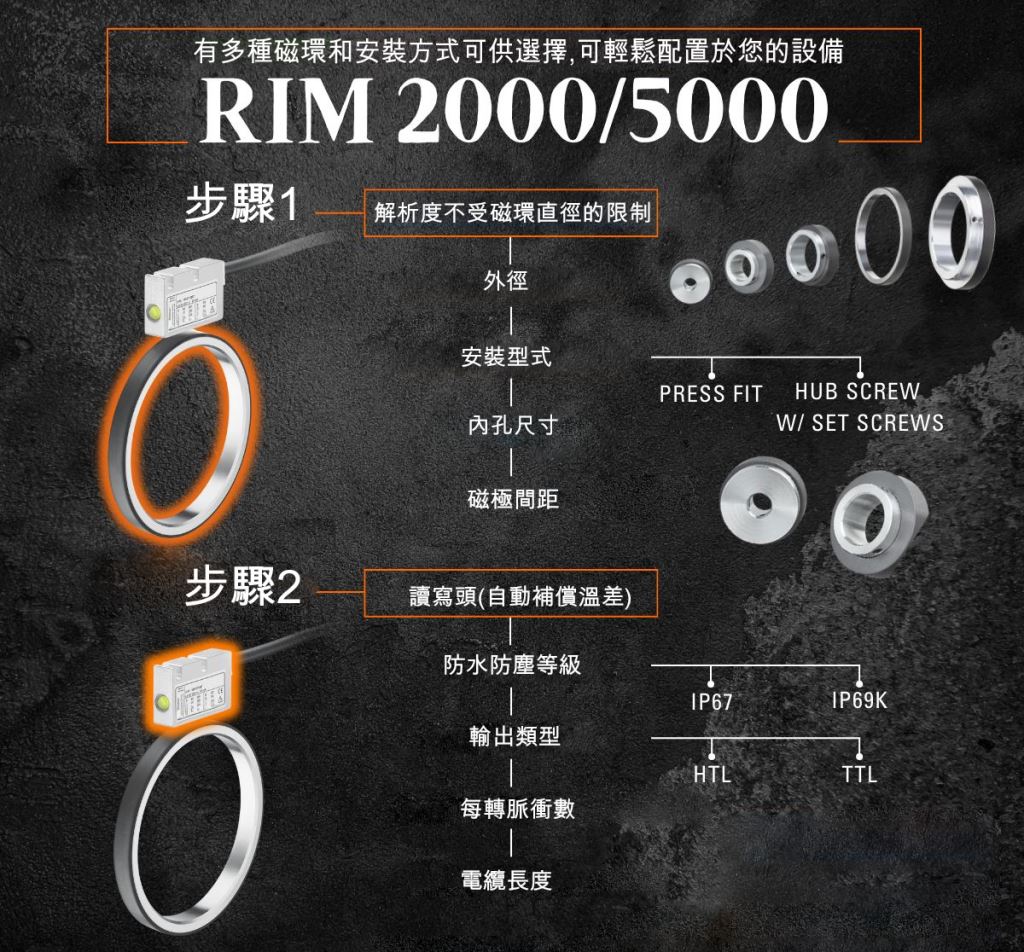

Kuebler Rim2000/5000 Incremental, programmable bearingless encoder

|

|

Programmable via programming device with touch display. Freely selectable resolution up to 999 999 ppr independent of the magnetic ring diameter.

Influences due to individual installation and temperature differences during operation are automatically compensated in the sensor head.

|

|

|

|

DRF Corporation is the exclusive distributor of KNF in the Taiwan market. Currently we are planning to expand our portfolio of products.

|

|

|

Products / Service Introduction

|

|

KNF liquid pump - Simdos 10

|

|

It is the ideal solution for accurate, reliable and stable dosing applications.

|

|

|

World’s Smallest of Its Kind. 24.2 mm in length only (with brushless DC motor) Transferring from just a few milliliters to up to 500 ml/min at a constantly.

|

|

|

KNF Diaphragm Liquid Pumps - FL 10

|

|

|

The FL 10 can operate for more than 10,000 hours and is waterproof and dust proofed by IP 65 to handle the most demanding work.

|

|

|

|

The company was founded by Norbert Meier, in Ludwigshafen in 1965. From the very early days, he concentrated on the development and production of connectors and fittings in small nominal diameters manufactured exclusively from special plastics. This technology has since established itself in practice and our modular product system continues to be used in a very wide range of applications. True to the motto, “everything from a single source”, we offer you high- quality and reliable products. Over the course of the years, a whole range of very successful products and product lines evolved that have established themselves as standard solutions on the market. We will also continue to change in the future: we will adapt to the new challenges of the market as well as the increased needs of our customers and look forward to a continued good cooperation with you.

|

|

|

Products / Service Introduction

|

|

5E113 electric actuator precision controls valve

|

|

- Analogue controls : 0~10 V,4~20 mA。

- DN04 G1/4” female thread, DN08 G1/2” female thread

- Materials : PP,PVDF,PTFE

- Sealing ring : FPM,FKM,FFKM O-ring

- Liquid Flow rate controls : 1~30 l/h,1~200 l/h,50~500 l/h

- Gas flow rate controls : 3~150 l/h,40~675 l/h,100~1,000 l/h

- High precision repeatability

- Precision rate : 1 % @ pulsation inlet pressure under 0.5 bar g。

|

|

|

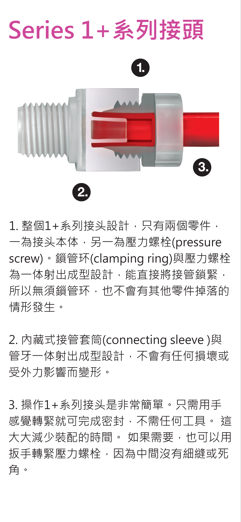

Series 1+ clamping free connector

|

|

- The 1+ connector consists of just two parts, the connector body and the pressure screw

- The clamping ring is incorporated into the pressure screw

- The thread and connecting sleeve are integrated inside in the connector body

- They cannot be damaged and are thus protected against external effects

- One pc design of connecting sleeve with body are plastic injection molding, completely leak-proof with only “ hand-tight” no tools are required

|

|

|

7G300 chemicals vacuum injector

|

|

- Use compressed air to create vacuum to draw liquids or gases even aggressive chemicals

- Materials : PFA,PVDF,PP

- Temperature resist : 180 degree C@5 bar g

- Applications : Semiconductor wafer high etching and cleaning process of suction of H2SO4 chemicals liquids at 150 degree C,on-line Gas Continuous Emission Monitoring Systems vacuum suction,chemical plants chemicals suction,medical equipment vacuum sampling

|

|

|

|

Erhardt + Leimer (E+L) is an expert in supplying customized solution and possesses, specialist know-how in process optimization system and automation technology for web guiding, tension control, width measurement, weight measurement system…etc.

Our products are used in various industries – textile, film, paper, tire, non-woven, packaging, corrugated, battery etc. Founded in 1919, the Augsburg-based company is nowadays engaged worldwide in production and sales.

|

|

|

Products / Service Introduction

|

|

|

With EL.NET we provide the tools you need to master Industry 4.0 processes. EL.NET will optimize your entire production process on the basis of a digital, network-capable, IoT-capable, and web-based system architecture. The system can be adapted without any problems to your current production processes and to your future production setup.

|

|

|

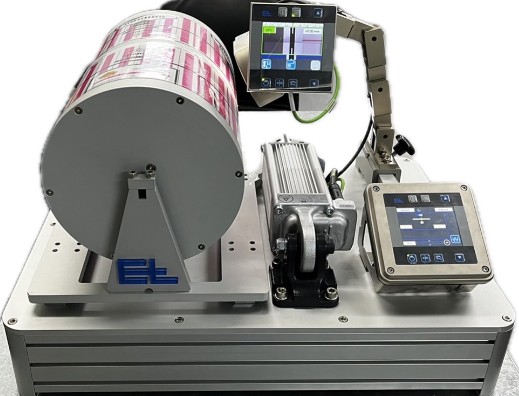

ELTENS-PD21, PD50, CV22, PA62

|

|

|

The E+L program ELTENS is used to log and assess the measurements from up to 8 web tension sensors. These web tension sensors form part of independently operating systems that are connected together via Profinet Or Ether net IP. Actual measurements or measurements from a file can be displayed graphically. Different sections of the data can be viewed and the scaling changed.

|

|

|

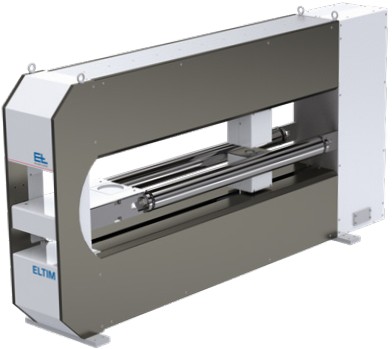

ELTIM-UltrasonicBasic Weight Measurement

|

|

|

Function

Based on ultrasound technology, the basis weight of a running web is accurately determined online and contactlessly. The detection of the basis weight is performed either with the aid of a traversing sensor head or, alternatively, with fixed sensor heads across the entire width of the web for 100% profile measurement. In addition, the thickness can also be calculated by entering the material-specific density.

Area of use

ELTIM basis weight measurement systems are used predominantly in flat extrusion and coating systems.

Application

A basis weight measurement system is normally installed after a process for quality control. In coating systems, in order to calculate the correct material application, it is necessary to measure both the substrate before the process and the coated product after the process.

|

|

|

|

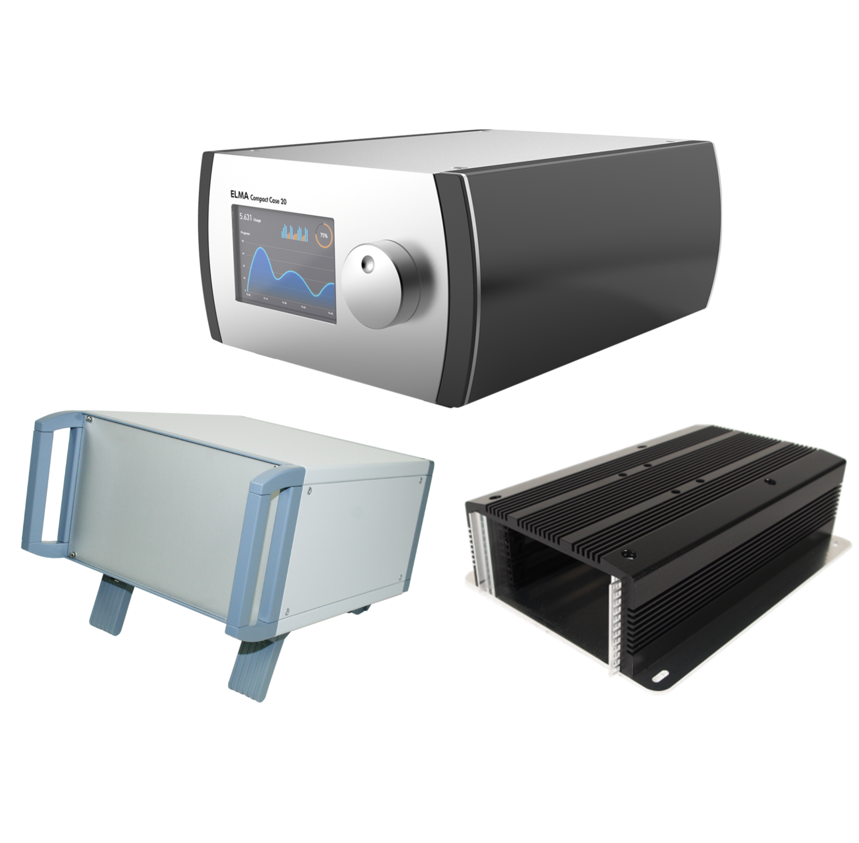

Elma Electronic is a global leader in embedded systems, found in Switzerland in 1960s, it has supplied rugged enclosures, chassis, 19'' rackmounts, rotary switches, and other components. In addition to standard products like VME/VME64x, CompactPCI series, PCIe and VPX, we also provide customed system and power solutions. Our market applications include industrial, semiconductor testing equipment, and military sectors.

Melchers Trading GmbH is the represented office of Elma Electronic in Taiwan.

|

|

|

Products / Service Introduction

|

|

|

The 19-inch sub racks are strictly based on the IEEE and IEC standards and are designed according to the areas of application. These can be supplemented directly by the manufacturer with all accessories such as card slots, front panels and ejector handles with card holders.

Rugged design enclosure platforms offer a wide range of opportunities for customer- specific design. Application specific topics such as EMC protection or heat dissipation are also considered.

|

|

|

|

Elma offers high quality switches, encoders& control knobs. Reliability and ruggedness are just two of Elma's core competencies for rotary switches. Panel and shaft sealing up to IP68 against dust and water are standard for all rotary switches. The shaft material for all switches is stainless brass or stainless steel – this is suitable for rugged environments. In order to guarantee years of undisturbed functionality and service life of the rotary switches, all electronic contacts are plated and provided with hard gold. In addition to a large selection of encoders, coding switches, selector switches, audio solutions and multifunctional rotary switches, Elma Electronic offers you also the right knobs and caps.

|

|

|

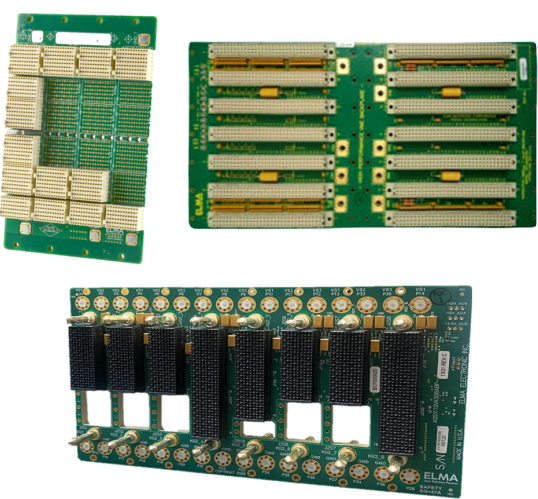

Backplane, CPCI Series, VPX VME backplane

|

|

|

High performance backplanes for VITA and PICMG open standards as well as custom implementations of other architectures. Product including AdvancedTCA, CompactPCI, OpenVPX VME/VME64x and other custom Backplane Architectures. Made in Germany or US.

|

|

|

|

As a leading manufacturer of precision sensor technology, we are shaping the future. Our systems are used whenever accuracy and performance are crucial to success. In machine building and automation as well as in satellite technology and in the production of next-generation batteries and computer chips. As a globally active group of companies, we are making a decisive contribution to the world of tomorrow - and have been doing so for more than 56 years.

We strive for greater precision in our products and thus promote innovation. Our displacement sensors achieve resolutions down to the sub-nanometer range, which is less than a millionth of a millimeter. These are used, for example, in semiconductor lithography machines in ultra-high vacuum.

In order to implement such high performance in series products, we rely on the competence network within our group of companies. Consulting, product development, application, electronics, optics, image processing, micromechatronics, simulation, software, system integration, production and quality - all from a single source.

|

|

|

Products / Service Introduction

|

|

|

confocalDT Confocal Displacement Sensor

|

|

|

The confocalDT sensors product range stands for the highest precision and dynamics in confocal chromatic measurement technology. These sensors enable high-precision and fast measurements for both distance and thickness measurements of transparent objects. In addition, innovative controller and sensor technologies ensure high signal stability on all surfaces. The high-performance sensor portfolio enables the solution of a wide range of measurement tasks, e.g., in flat glass production, in measuring machines and in semiconductor machine construction.

|

|

|

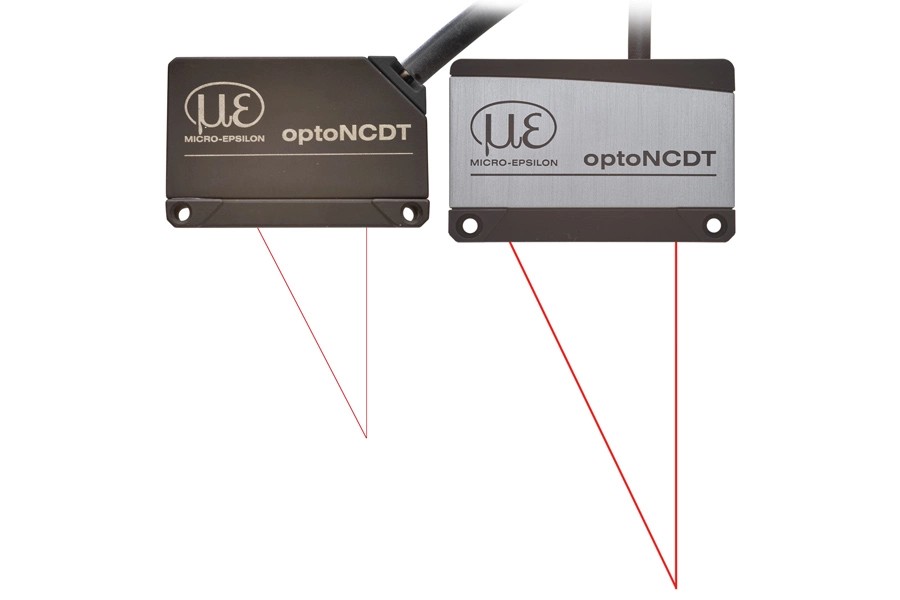

optoNCDT Laser Triangulation Displacement Sensor

|

|

|

optoNCDT laser sensors have set milestones for industrial laser displacement measurement. Whether for displacement, distance or thickness measurement, Micro-Epsilon laser sensors are considered one of the best in their class. These laser sensors are used e.g. in measurement and monitoring tasks in factory automation, electronics production, robotics and vehicle construction.

|

|

|

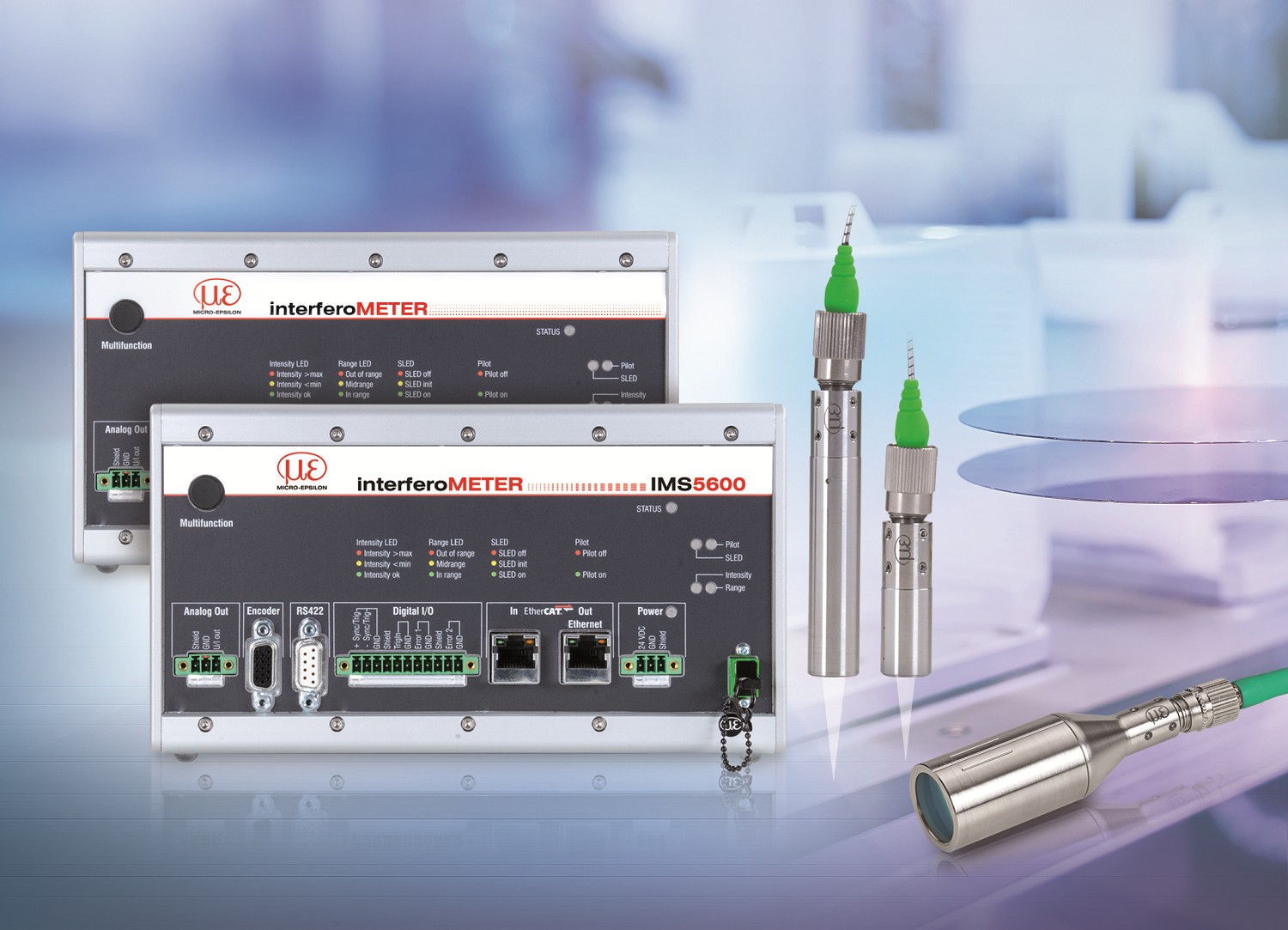

interferoMETER high precision displacement/thickness sensor

|

|

|

The innovative white light interferometers from Micro-Epsilon set a benchmark in high-precision distance and thickness measurements. The absolute interferometers enable stable measurement results with sub-nanometer resolution offering a comparatively large measuring range and offset distance. The interferometers are used for absolute distance and thickness measurements of transparent objects and wafers.

|

|

|

ODU (HK) Trading Co., Ltd.(J433)

|

|

|

The ODU Group is one of the world’s leading suppliers of connector systems, employing 2,800 people around the world. In addition to its company headquarters in Muehldorf a. Inn (Germany), ODU also has an international distribution network, production and product development sites in Sibiu / Romania, Shanghai / China, Tijuana / Mexico and Camarillo / USA. ODU combines all relevant areas of expertise and key technologies including design and development, machine tooling and special machine construction, injection, stamping, turning, surface technology, assembly and cable assembly. The ODU Group sells its products globally through its sales offices in Austria, China, Denmark, France, Germany, Hong Kong, Italy, Japan, Korea, Sweden, UK and the US, as well as through numerous international sales partners. ODU connectors ensure a reliable transmission of power, signals, data and media for a variety of demanding applications including medical technology, military and security, automotive, industrial electronics, and test and measurement.

|

|

|

Products / Service Introduction

|

|

ODU MINI-SNAP® PUSH-PULL Circular Connector

|

|

|

ODU MINI-SNAP® is the ideal self-locking circular connector for a wide range of applications. Whether used for transmitting power, signals, data or other media, this circular connector in its robust metal connector plug housing impresses customers with its exceptional quality, high reliability and ideal handling characteristics.

The PUSH-PULL principle reliably ensures that the connector will not come loose during application in practice: Once plugged in, the ODU MINI-SNAP® locks itself into the receptacle automatically. It cannot be separated by pulling on the cable. Instead, the connector can easily be separated from the receptacle by pulling on the outer housing.

|

|

|

ODU-MAC® Modular Attachable Connector

|

|

|

The ODU-MAC®'s flexible, modular design enables multiple transmission types to be combined within one connector. Whether signal, power, high current, high voltage, coax, high-speed data transmission, fiber optic and other media such as air or fluid – all types can be selected from the module variety and integrated into the individual connector solution.

Many options are available for a variety of applications in industry or test & measurement technology. For example, installed in the stable frame for rack and panel applications or for automatic docking as well as in a housing version.

The result is an effective, compact and attractive complete connection that is unrivalled in terms of functionality. Confusion due to many connections is a thing of the past – an ODU-MAC® customized to meet your requirements is todays' solution.

|

|

|

|

ODU-MAC® Power Connector solution combines high current and high voltage with thermocouple, signal and high-speed signal in one interface. It enables safe transmission with touch protection in a robust connector. Different variants are available enabling it to be tailored to the chosen application.

|

|

|

Phoenix Contact Co., Ltd. (J318)

|

|

|

Phoenix Contact is the worldwide market leader of components, systems and solutions in the area of electrical engineering, electronics and automation. Connecting, distributing, and controlling power and data flows - we have been developing the right products for this purpose since 1923. Whether in industrial production facilities, in the field of renewable energies, in infrastructure, or for complex device connections: our solutions are used wherever processes must run automatically. Above and beyond their pure function, they help our partners to develop sustainable applications with more efficient processes and reduced costs.

|

|

|

Products / Service Introduction

|

|

|

Use the feed-through terminal blocks, multi-level terminal blocks, and multi-conductor terminal blocks from Phoenix Contact for space-saving connection of two or more conductors in just one terminal block. The terminal blocks are characterized by their flexible bridge ability and optimum marking options.

|

|

|

|

For efficient operation, you need reliable supply solutions consisting of surge protection, power supply, device protection, and energy monitoring with the corresponding measurement technology. Choose us as a partner who provides you with everything from a single source, from selection to installation right through to operation. With the extensive Phoenix Contact portfolio, you not only ensure very high system availability, but also efficient and sustainable system operation. To avoid unplanned system failures and downtimes.

|

|

|

CCS charging cable for up to 1,000 kW

|

|

|

High Power Charging with new cooling concept, with the second generation of our CHARX connect professional liquid-cooled CCS charging connectors, we are taking ultra-fast HPC charging to a new level. Thanks to a newly developed cooling concept, the CCS charging cables can now transmit significantly higher charging powers of up to 1 MW in Boost Mode or 800 kW permanently.

|

|

|

Pixoel Taiwan Technology Limited (J232)

|

|

Pixoel Taiwan Technology Limited, established in Taiwan in 2016, is the exclusive partner of IDS Imaging Development Systems, the leading German industrial camera manufacturer, in Great China (Taiwan, HongKong and China).

Over the past 10 years, Pixoel Technology has established offices in Shenzhen, Shanghai, Chengdu, Changsha, Hong Kong, and other locations. The company focuses on 2D and 3D vision applications and solutions, and has accumulated extensive professional experience with IDS products and technology. As the sole strategic partner of IDS in the Greater China region, Pixoel provides customers with the most professional and high-quality services!

|

|

|

Products / Service Introduction

|

|

|

Ensenso currently offers four major series. The Ensenso N, Ensenso C, and Ensenso X series are based on the unique "projected texture stereo vision" technology. Each 3D camera in these series integrates two CMOS sensors and a projector that projects high-contrast textures onto the surface of objects. The Ensenso S series, on the other hand, utilizes a laser light combined with AI technology. This design achieves cost reduction and a lightweight form factor without requiring extremely high precision data.

|

|

|

Precitec Asia Ltd. (K202)

|

|

|

Precitec is an expert to provide the best chromatic confocal sensors, interferometric sensors, and laser process head & monitoring system.

Precitec was founded as a small engineering office in 1971 and is now a worldwide operating company for laser technology and 3D measurement technology. Innovation, customer focus, CAN-DO attitude, spirit, and social responsibility form the core pillars of our trade as a reliable and long-standing business partner.

We will present the new generation line sensor, point sensor, welding head, and welding monitoring system. Come to see us!

|

|

|

Products / Service Introduction

|

|

The Flying Spot Scanner (FSS) 310 uniquely combines OCT with wide field-of-view scanning, and solves the problem that ultra-precise measuring systems are normally very slow and extremely expensive.

The FSS 310 has a flexible, fast-moving measurement point within the field of view which enables a ROI inspection in ultra-short cycle times – without compromising accuracy. This device measures the total thickness variation (TTV), bow, warp and voids of an entire 12-inch wafer in a single scan.

Broad applicability - In combination with devices from the CHR 2 IT family, the fully variable scan trajectories programmable by the user enable thickness and distance measurement of Si, doped Si, GaAs and SiC wafers. The FSS not only measures bow, warp and TTV but also detects voids on wafers, performs thickness measurements of semiconductor component coatings (e.g. partial foliation of wafers) as well as measuring the bow of individual dies on wafers prior to further processing.

|

|

|

The chromatic confocal line sensor CHRocodile CLS 2 is the ideal tool for precise 3D inline quality control in harsh industrial environments. It is highly suitable for applications in consumer electronics and semiconductor industries, such as inspecting the topography of smartphone housings or conductor chips, as well as measuring and inspecting micro bumps or detecting die cracks.

|

|

|

|

The Laser Welding Monitor (LWM) detects process irregularities in a fully automated production environment and is the tool of choice, to meet your quality requirements. Every single laser weld is monitored evaluated and documented to ensure 100% traceability and transparency in series production.

DETECTION OF TYPICAL WELDING DEFECTS:

• Change of laser power and focus position

• Gap between upper and lower sheet

• Spatter and pores created during the laser process

• Contaminated components

The LWM can be adapted to almost any customer application, facility and infrastructure. The sensor‘s high dynamic range enables monitoring from high power welding applications to micro welding applications - at the push of a button using the same hardware. It captures data from any type of process, whether it‘s deep penetration or heat conduction welding applications, welding with or without keyhole, or a combination of both CW or pulse laser are available as modes.

In addition, the LWM 4.0 sensor is available for infrared, green or blue laser sources. The photodiodes are adapted to the laser source.

|

|

|

Road Ahead Technologies Consultant Corp. (J326)

|

|

|

RATC established in June 30, 1996, started with a professional technical team to provide 3D engineering technology and consulting services. RATC is the first company in Taiwan to advocate RE‧Reverse Engineering and RP‧3D printing in 80s.

Today, RATC provides cross-strait service in Taiwan and Mainland China, and continues to support customers with innovative, proactive and comprehensive 3D technology.

Our services include: reverse engineering, 3D printing, 3D inspection and industrial design services for the industrial, semiconductor, aerospace and medical industries.

|

|

|

Products / Service Introduction

|

|

|

The lightweight ZEISS T-SCAN hawk 2 with GOM Inspect. The 3D scanner T-SCAN hawk is portable, precise and made to make a difference. In combination with the pre-installed GOM Inspect software, it’s a powerful solution that assists you along every step of your task. From capturing high quality 3D data to delivering high quality results: It’s made to simplify processes. It’s made for you.

|

|

|

|

The ZEISS METROTOM is an industrial computed tomography system for measuring and inspecting complete components made of plastic or light metal. With traditional measuring technology, hidden structures can only be inspected after the time- and cost-consuming process of detroying the component layer-by-layer.

With ZEISS METROTOM computed tomography system, numerous component characteristics are scanned in one run. The resulting measurements are precise and traceable. Unlike contact measuring methods, ZEISS METROTOM is signifcantly faster when capturing numerous measuring points.

|

|

|

|

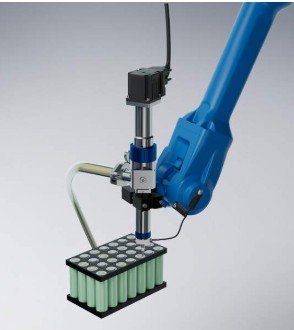

ZEISS ScanCobot is a mobile measuring station with a collaborative robot, a motorized rotation table and powerful software. It is espacially suited for efficient quality control of small and medium-sized parts made of plastic, metal for cast iron. The system can be used during the preproduction phase such as design and prototping and during the market launch. In a short measuring time, the optical 3D scanner ATOS Q captures quality information at a high level of detail, providing a reliable basis for easy interpretation. To measure a part completely, the sensor must face the part from dfferent directions. The ZEISS ScanCobot uses a collaborative robot to perform this normally manual work process. Combined with the motorized rotation table, the robot can move along the sensor positions very quickly one by one. Efficient scanning and subsequent automatic inspection speed up quality control processes.

|

|

|

SCHMIDT Technology. (J228)

|

|

SCHMIDT Technology is a family-run, medium-sized enterprise at the highest technological level. The success speaks for itself:

Today, products and services from SCHMIDT Technology are exported to over 80 countries of the world. The safety and quality of SCHMIDT Technology products make them unique on the global market and thus sought after for decades. The international orientation of the company and the combination of creative and intelligent solutions, together with economic and efficient manufacturing in Germany, lay the groundwork for the successful future-oriented position of the enterprise. Because of this, SCHMIDT Technology is valued internationally as a solid, dependable and competent partner. The outstanding characteristics of a successful company must include a strong visionary innovation potential.

SCHMIDT Technology recognized this at an early stage and invested ardently in the fields of research and development. At the same time, the company traditionally keeps in close contact with external research institutes and universities. As a result, the name SCHMIDT Technology is associated with highest quality standards worldwide. In keeping with this, SCHMIDT Technology holds all relevant quality certificates such as DIN EN ISO 9001.

Machine

The well-balanced assortment of the SCHMIDT® Press Systems are used in the metal-forming and assembly technologies in such work steps as assembling, flaring, joining, pressing, testing, bending, embossing, forming, stamping and riveting. From simple, manual workplaces to computer-controlled, fully automatic assembly machines with integrated quality control, the assortment covers all levels of automation employed today.

|

|

|

Products / Service Introduction

|

|

SCHMIDT ServoPress/ElectricPress/TorquePress with Closed-loop force control technology

|

|

|

An efficient assembly process is crucial for the success of your company. Parts with individual tolerances must be joined to create an accurate assembly. Electrically driven screw type actuators (servo presses) are ideally suited for this task. The high precision SCHMIDT® ServoPress paired with a specifically designed SCHMIDT® PressControl 700 or 7000 offers the perfect solution both as a single work cell or in an automated assembly line, combining full closed loop force and position control with full force and distance monitor.

All SCHMIDT® ServoPress modules are designed to press to their full load capacity, incorporate ram position measurement technology, integrated load cells, automatic spindle greasing and have a built-in overload protection clutch (except No. 605). When equipped with our light curtain/guarding, SmartGate or Smart-Guard safety options, they meet the most current EC machinery directives for safety and can be provided with type approval documentation if required

|

|

|

|

Efficient manufacturing requires appropriate means of production– not always automation. In particular, with small production runs, manual presses are often the most cost effective solutions.

We are continually developing the range of manual presses so that you can achieve your production targets. The expertise we have gained from our exposure to numerous production applications has been implemented in our new models. Therefore, we can offer a wide range of manual presses to suit all requirements.

|

|

|

SCHMIDT ® PressControl 75, 700 and 7000 are control units of the latest generation, which allow the design of modern production processes – from the single workstation to complete automation. You benefit from our competence in:

- Closed-Loop Force Control

- Safety technology – EC type approved machines

- process measurement technology – simultaneous measurement technology in the process

- process documentation

The control systems have the following features:

- Efficient due to intuitive user interfaces on touch / multi-touch screen

- Fast and safe setup of processes in a clearly arranged window, simple parameterization for manual ram movement and transfer of the actual parameters force and path to the motion blocks (teach-in) for the PressControl 700 and 7000 controls in combination with ServoPress/TorquePress/ElectricPress

- The integrated PLC allows the control of additional inputs/outputs or sensors/actuators and thus the application-specific set-up of the workstation or system

- The integrated measurement data acquisition is insensitive to interferences (EMC). This results in a high measurement reliability of the entire system

- With the integrated safety technology, the entire system becomes an EC type-approved single workstation

- Service functions enable simple and efficient maintenance

Guarantee of complete process documentation with clearly traceable component assignmen

|

|

|

TÜV Rheinland Taiwan Ltd.(J431)

|

|

|

An internationally leading independent third-party testing, inspection, certification, training, and consulting organization, TÜV Rheinland has over 150 years of experience. TÜV Rheinland employs over 4,000 people in the Greater China region, and operates in four Business Streams: Industrial Services & Cybersecurity, Mobility, Products and People & Business Assurance.

The group is involved in all important areas of business and life. This starts with the energy sector and the consumer goods industry, and includes the automotive industry, basic materials and investment goods, environmental technology, trade, construction, aviation, railway technology, the IT sector, information security and data protection, as well as the education and healthcare sectors.

TÜV Rheinland has long been synonymous with rigorous high-quality testing and certification services and provision of a diversity of professional assessments from an impartial and independent perspective. We provide local companies with one-stop solutions that comply with safety, quality, and environment-friendly requirements.

|

|

|

Products / Service Introduction

|

|

|

Functional Safety Services-Training, Certification, Workshop

|

|

|

Training Course and Certification

- Functional Safety / Cyber Security Engineer Training

- Functional Safety Management System Certification

- Safety-Related Product Certification

- ISA/IEC 62443 Certification

Workshop

- Calculation of Probability of Dangerous Failure (PFH/PFD)

- Failure Modes and Effects Analysis (FMEA)

- Software Assessment and Environmental Tests (incl. EMC)

|

|

|

Industrial Functional Safety Services Scope

|

|

- Functional Safety of E/E/PES

- ISO 13849 Safety of Machinery – Safety-Related Parts of Control Systems

- IEC 62061 Functional Safety of Machinery Industry

- IEC 61800-5-2 Adjustable Speed Electrical Power Drive Systems

- IEC 62443 Industrial Communication Networks - IT Security for Networks and Systems

- Cybersecurity Resilience Act

|

|

|

Safety Assessment and Personnel Training for Production Line

|

|

- Safety Assessment of Machineries in the Plant

- Smart Manufacturing Line / Mechanical Integration System

- One Stop Service for Global Market Access

- CE Marking (Machinery / LVD / EMC / RED Directive)

- Machinery Risk Assessment

- EN ISO 13849 Safety-related Parts of Control System Assessment

- Product cTUVus Certification for US and Canada

- US Field Evaluation Service (FES)

- China Robot (CR) Approval

|

|

|

Safety Evaluation and Personnel Training of Automatic Equipment

|

|

- Industrial Robots/Service Robots

- (AGV) Auto Guided Vehicle / (AMR) Autonomous Mobile Robot

- Intelligent Warehousing System

- Commercial 3D Printer

- SEMI Approval of Semiconductor Equipment

- Metalworking Machines / Special Purpose Machines

- Machines Listed in Annex IV of MD (2006/42/EC)

|

|

ViscoTec Hong Kong Limited(K401)

|

|

|

ViscoTec is expert in medium to high viscosity fluid handling and treatment systems and equipment made in Germany. We offer high-precision dispensing pumps and systems for automated dispensing applications. Whether if it comes to adhesive dispensing, dosing applications or potting – our products fulfill the requirements of even most complicate applications. Our dosing systems and components are required for conveying, dosing, dispensing, filling as well as for emptying and treating fluids and pastes. They function regardless of viscosity: For all materials with a viscosity of up to 7,000,000 mPas. Handling is pulsation-free and particularly low-shear.

ViscoTec provides comprehensive consultant and customized solutions for each application requirement for our customers. Our high-quality products are used in a wide variety of industries such as e-mobility, aerospace, electronics, 3D printing, food, pharmaceuticals, cosmetics, and medical technology. preeflow® is brand by ViscoTec for micro-dispensing application. Puredyne® is a new brand by ViscoTec for 3D bioprinting awarded reddot winner 2022.

|

|

|

Products / Service Introduction

|

|

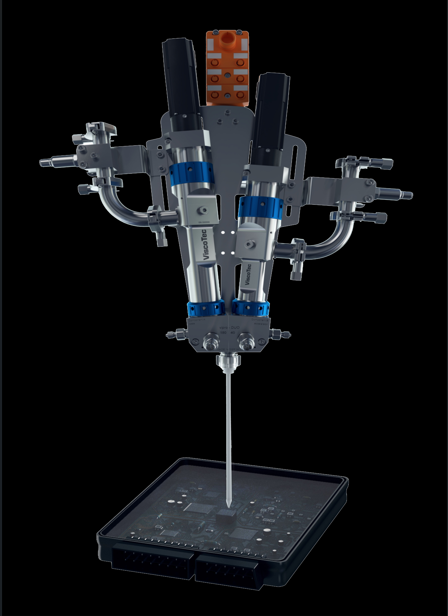

vipro-DUO (2-component Dispenser)

|

|

|

vipro-DUO is a new 2-component dispenser designed for the precise dispensing of materials with different viscosities. Here are its main features:

- ModularDesign: Each side is equipped with five different dispenser sizes, with mixing ratios ranging from 1:1 to 100:1.

- Optimized Mixing Block: Ensures materials are handled gently during processing, maintaining consistent density during dispensing

- Reduced Installation Bracket: Optimizes installation space, facilitating integration with automation applications.

- Dual Outlet: Ensures reliable ventilation of the mixing block.

- Front-Mounted Metering Pressure Sensor: Used for process monitoring and easy calibration.

- Progressive Chamber Technology: Ensures precise metering and long product life even with high filler content.

|

|

|

vipro-PUMP (1-component Dispenser)

|

|

|

The core of vipro-PUMP is the innovative, modular design of the dispenser. On the one hand, the separable rotor assembly allows fast installation and removal of its components – these speeds up service and maintenance work, reduces machine downtimes and minimizes spare part and operating costs. On the other hand, variable rotor and stator materials ensure optimum dispenser performance – for example, a ceramic rotor with matching stator is ideally suited for abrasive media, while an HVC rotor is used for standard applications (e.g. adhesives).

An enlarged pump inlet minimizes pressure loss, improves the material flow and allows easy attachment and detachment of the hose supply.

Two larger modular bleeding openings ensure a user-friendly and clean bleeding process and ultimately help to guarantee dosing with no air bubbles.

The new stator design has an anti-rotation device and a defined non-positive connection to allow easy and intuitive assembly. Various drives can be attached to the dispenser using a locking ring and the newly designed coupling.

|

|

|

preeflow® eco-PEN XS 180 (Micro-dispenser)

|

|

|

preeflow® eco-PEN XS 180 is a high precision volumetric micro dispenser designed for dispensing extremely small quantities of materials with varying viscosities. It excels in applications requiring precise metering, making it suitable for electronics manufacturing, medical technology, and other industries with high precision requirements. This dispenser features a rotating, pressure-sealed displacement system that ensures consistent and reliable dosing without altering the dispensed material. It can handle various viscosities and dispensing amounts in the nanoliter and microliter range.

|

|

|

WAGO Contact Limited (K206)

|

|

Established in 2009, WAGO Contact Limited is subsidiary of WAGO Kontakttechnik GmbH & CO. KG. in Taiwan. Our main goal is to serve customers in Taiwan.

Customers have always been the core essence of WAGO. We serve with reliable solutions and partnership-based consulting, which have been inextricably linked with our name since 1951. Our complete product line includes rail-mounted terminal blocks, installation connectors, lighting connectors, PCB terminal blocks, pluggable connectors, programmable control systems, interface modules, power supplies, industrial switches and pluggable connection systems. WAGO's continuous innovation and development in a wide range of industrial applications makes us your most competent and reliable partner.

We combine partnership with inspiration, our vision is to be the backbone of a sustainable and smart connected world. That makes us WAGO – and you successful

|

|

|

Products / Service Introduction

|

|

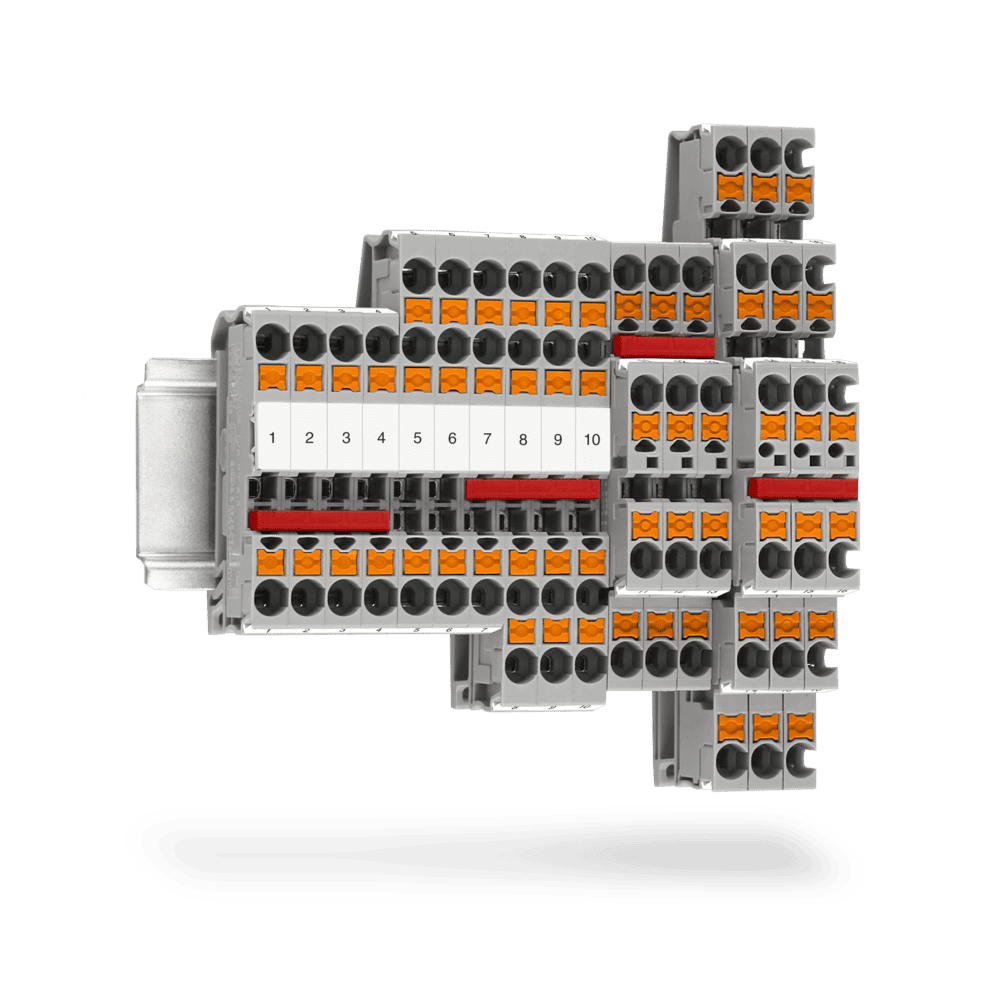

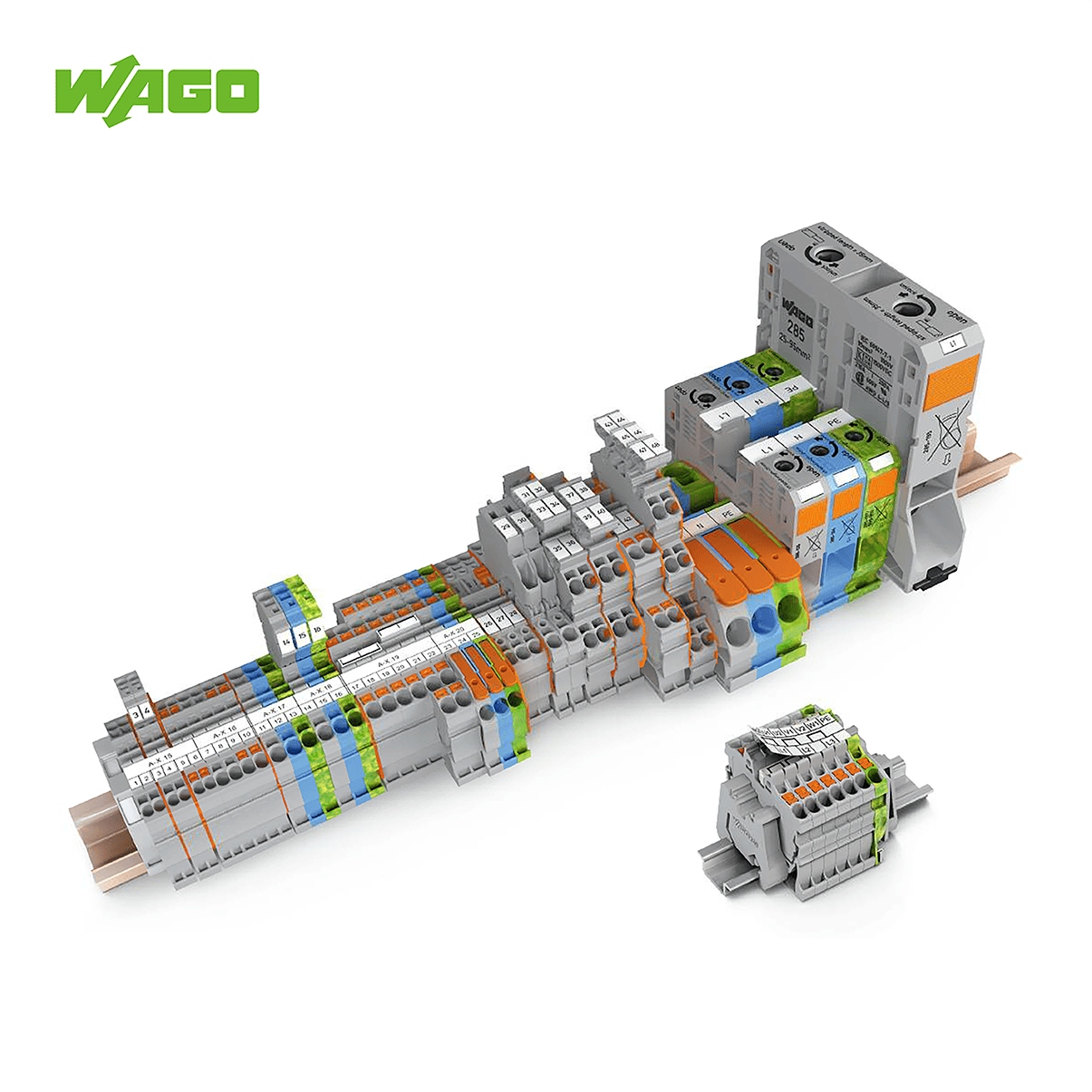

TOPJOB® S Rail-Mount Terminal Blocks

|

|

SIMPLY PUSH PERFORMANCE TO THE TOP WITH TOPJOB® S RAIL-MOUNT TERMINAL BLOCKS

Save time and avoid errors in realizing your switchgear: Thanks to reliable push-in connection technology and 3 ways to terminate wires - Levers, Push-buttons and Operation slots.

Our rail-mount terminal blocks are incredibly quick and easy to use, both in the workshop and the field.

|

|

|

|

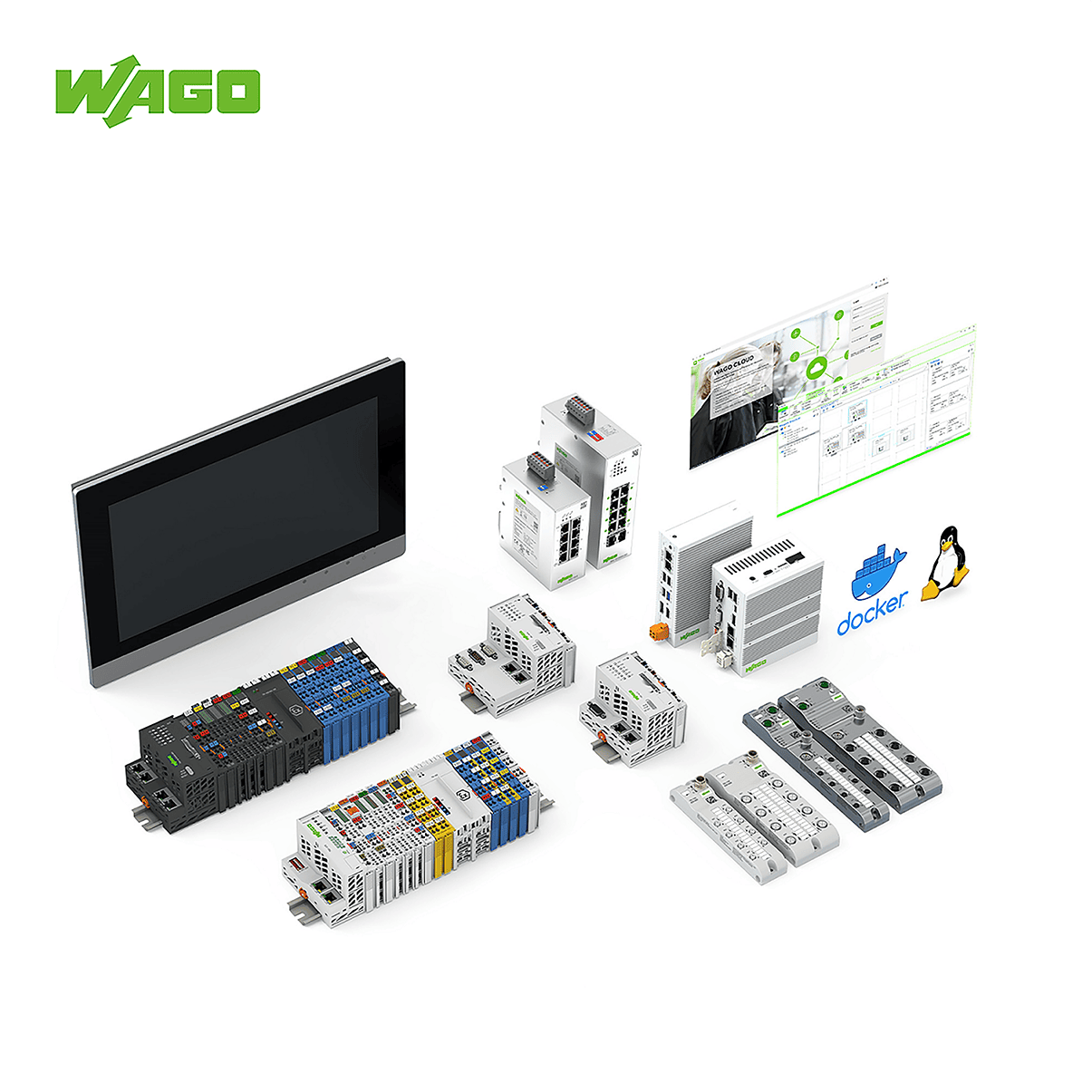

WAGO Automation Technology includes a comprehensive range of

automation products - PLCs, modular remote I/Os, Industrial switches,

HMI deivces, and engineering softwares.

These flexible and scalable solutions support various industrial

protocols, making them suitable for everything from standalone

machines to complex system integration.

|

|

|

|

WAGO Interface Electronics deliver modular solutions for signal

processing, control voltage conversion, and system power - including

relays, power supplies, and energy measurement modules.

Designed to optimize energy efficiency and availability, these products

support sustainable and future-ready automation systems.

|

|

|

|

GTO German Business Alliance

|

|

|

If you don´t want to receive any more messages (to: unknown@noemail.com) any longer, you can unsubscribe free of charge at any time.

Deutsches Wirtschaftsbüro Taipei

19F-9 No. 333 Keelung Rd

110208 Taipei, Taiwan

+886 2 87585800

info@taiwan.ahk.de

www.taiwan.ahk.de

|