Product family | Technology | Medium | Oxidation gas |

|---|---|---|---|

CT-BW | gas burner | O2 or compressed dry air | |

CT-PW | plasma torch | compressed dry air | |

CT-TW | electrical heater | ambient air | |

CT-TW-H | electrical heater, H2 | ambient air | |

CT-W | water | - | |

CT-D | granulate | - | |

CT-D-E | granulate | - | |

CT-D VLC | granulate | - | |

CT-PF | filter | - |

Innovative solutions for a clean environment

As a technology leader in industrial point-of-use waste gas treatment, we contribute to a cleaner future with our end-to-end solutions. Our systems effectively reduce harmful emissions, including highly persistent PFC gases like CF4, SF6, and NF3, which have extreme global warming potential. By efficiently destroying these hazardous gases at their point of use, our gas abatement systems help create a greener environment.

We take responsibility for managing your emissions and adapt proven processes such as pollutant burning, scrubbing, filtration or absorption to your specific requirements.

We take responsibility for managing your emissions and adapt proven processes such as pollutant burning, scrubbing, filtration or absorption to your specific requirements.

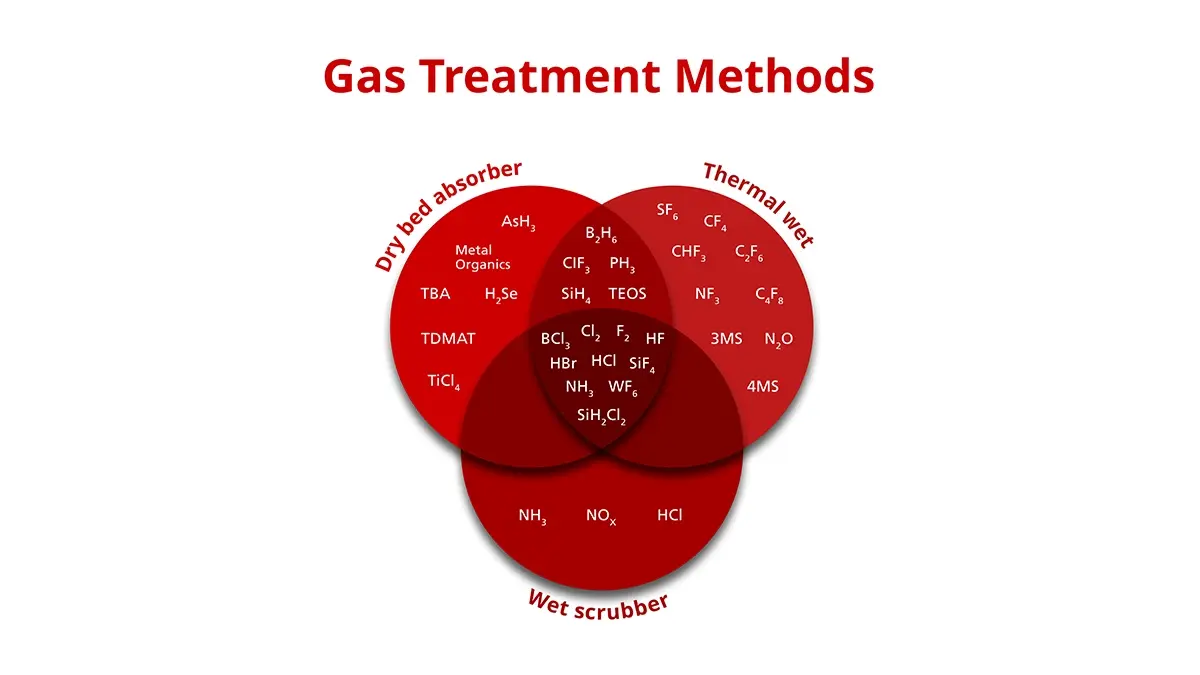

Types of gas abatement systems

Thermal gas treatment

Wet gas treatment

Dry bed absorber

Filter systems

Applications

Gas abatement systems from Pfeiffer are essential for maintaining a clean and safe production environment, particularly in the semiconductor industry. From etching, chemical vapor deposition (CVD), epitaxy, atomic layer deposition (ALD), ion implantation and thin film deposition to extreme ultraviolet (EUV) lithography, our advanced technologies ensure the reliable removal of hazardous process gases right at the point of use: thermal gas treatment, wet gas treatment, dry bed absorber and filter systems, or a combination of these.Each industry has unique requirements and safety standards. To discover the best gas abatement solution for your needs, contact our experts.

Gas abatement services

Ensuring the long-term efficiency and reliability of your gas abatement systems is our priority.

From installation and commissioning to maintenance, upgrades, and system checks, our expert team provides tailored support to keep your equipment operating at peak performance.

We also offer operating cost analysis, Fourier transform infrared spectroscopy (FTIR) gas measurements, spare parts supply, and disposal services, making sure your system remains safe, compliant, and cost-effective.

From installation and commissioning to maintenance, upgrades, and system checks, our expert team provides tailored support to keep your equipment operating at peak performance.

We also offer operating cost analysis, Fourier transform infrared spectroscopy (FTIR) gas measurements, spare parts supply, and disposal services, making sure your system remains safe, compliant, and cost-effective.

Designed for your process: Customized gas abatement solutions

The broad abatement product portfolio from Pfeiffer Vacuum+Fab Solutions includes optimal waste gas treatment solutions for every industrial installation.

Our in-house developed modular systems enable us to tailor each solution to your specific requirements.

Our in-house developed modular systems enable us to tailor each solution to your specific requirements.